Aluminum Casting Defect Solutions & Total Quality Control

“Better Melt, Better Casting.”

Solving the Unsolvable. Aluminum Casting Defect Solutions & Melt Quality Improvement Clinic using Thermal Analysis

Melt Quality Analysis & Diagnosis

Thermal Analysis transcends the limits of Flow Simulation. What is the decisive cause that simulations fail to assume?

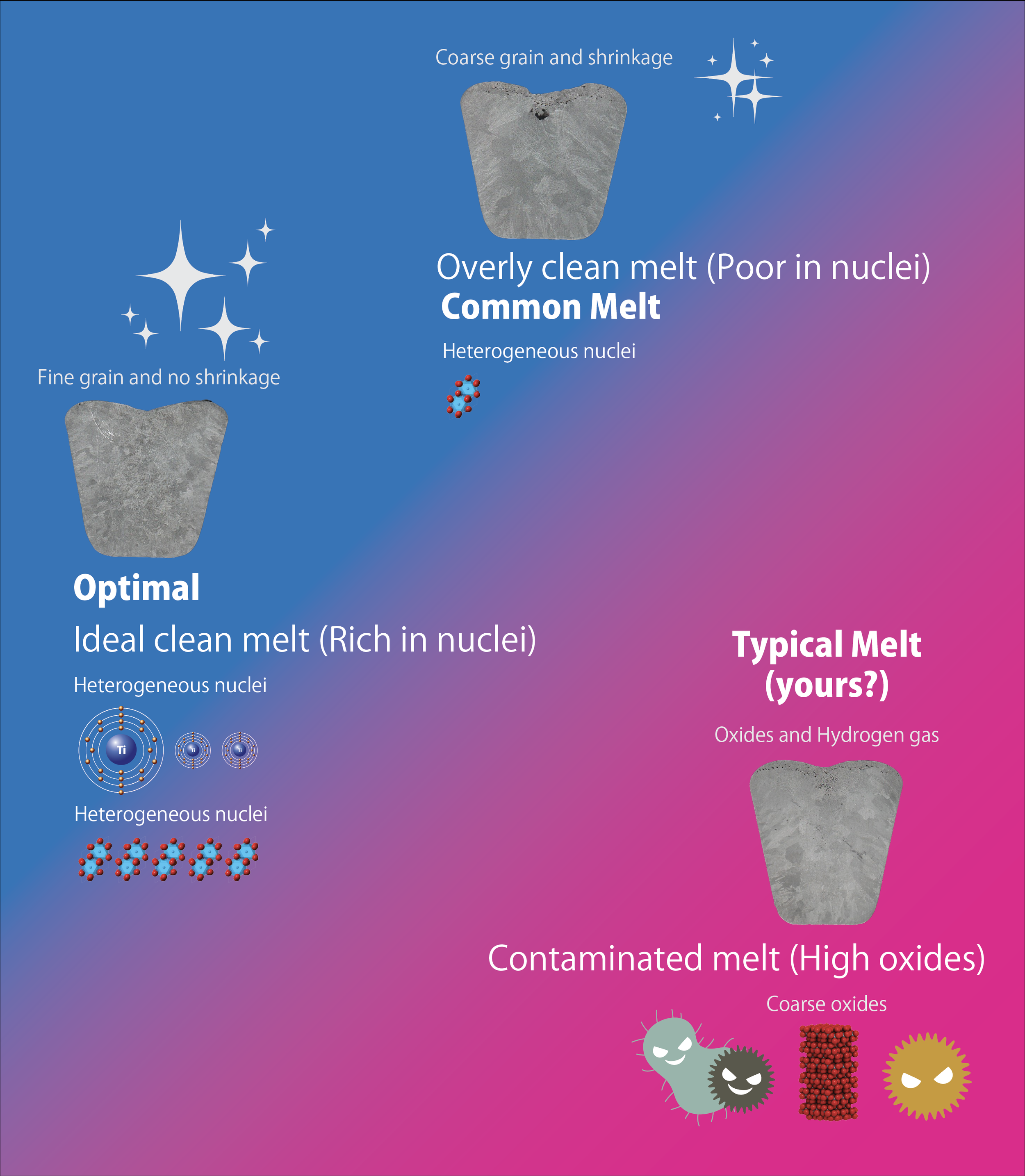

Countermeasures for aluminum casting defects caused by ingots or molten metal are KANAE's greatest specialty. Oxides in the melt can be "good" or "bad." Our thermal analysis technology has even proven the existence of "defects caused by overly clean melts," a phenomenon previously little known.

A real production floor is not a sterile condition like a controlled laboratory. That is why we provide technology tailored to the "Reality of the Shop Floor," where impurities and fluctuations exist, rather than theories based on ideal environments. Because the shop floor holds truths more complex than theory.

[Defects that can be unraveled by Thermal Analysis]

Hard Spots, Inclusions

Shrinkage, Micro-porosity, Combined porosity

Misruns, Cold shuts (Two-fold / Oxide films)

Corner shrinkage/cracking, Leakage

Decline in mechanical properties (Tensile strength, Proof stress, Elongation, Hardness)

T6 heat treatment failure (Ineffective heat treatment)

In addition to these many defect causes, the correlation with Hydrogen Gas is also now within our scope of analysis.

Why do casting defects persist even with flow simulation? Because a crucial factor is not being taken into account.

Analytical power that understands ingots worldwide We have analyzed aluminum alloy ingots from Japan, China, the Middle East, Europe, and around the world. Every country—and every manufacturer—has its own "habits." In factories where oxide and silicon management is lax, material properties can fluctuate drastically just by changing the season or production lot.

Good products can be made even with "Cheap Materials" Thermal analysis of the ingot reveals exactly what melt treatment is needed to produce high-quality castings. Even when using low-cost ingots or 100% return scrap to reduce purchasing costs, thermal analysis allows you to select the best option and apply the correct treatment.

Training to anchor technology in your organization If requested, we can conduct on-site surveys and lecture on optimal melt treatments and countermeasures based on analysis results. Regular follow-up training is also available to ensure the technology takes root on the shop floor.

First, please request an ingot analysis. If possible, please send return scrap (returns) and the flux you are currently using along with the ingots. This will allow us to create a highly precise diagnostic report based on the actual conditions of your production.

Material Analysis & Process Optimization Support

Thermal Analysis System

The same professional-grade equipment we use for technical consulting is available for your company. The greatest benefit of this system is the "Visualization" (Quantification) of aluminum molten metal quality.

Instead of relying on intuition or experience, the Production Engineering Department sets a "Passing Score" (Quality Standard), and the shop floor adheres to it. This establishes a workflow where Production Engineering and the Casting Shop can communicate using common numerical data, leading directly to stabilized quality and a significant reduction in defect rates.

High-Precision Sampling Cup for Thermal Analysis

Accurate measurement starts with a precisely calculated "Sampling Cup." KANAE’s cups are optimized specifically for the thermal analysis of aluminum melt, featuring perfected sand grain size, weight, and heat dissipation structure, along with a built-in high-precision thermocouple.

This level of measurement accuracy—achieved through dedicated design—cannot be replicated by cups meant for cast iron or other generic imitations.

Super Rapid Vacuum Porosity Tester

Standard vacuum solidification devices are meant to trap gas inside for evaluation. However, conventional devices have a slow vacuum speed, allowing gas to escape from the surface before the metal solidifies. This is exactly like trying to measure the carbonation level of "flat soda".

In many foundries, operators intentionally slow down the vacuum process to prevent bubbles from bursting or the metal from splashing. This puts the cart before the horse. Splashing is proof that excessive gas remains in the melt. If you slow down the process to let the gas escape, the analysis may show the gas level is "within limits," but the actual casting will still have gas defects. This creates a dangerous contradiction.

KANAE’s system uses "Rapid Vacuum" technology that leaves no time for gas to escape, allowing you to evaluate the "True Gas Content" without any deception.

Straight Grass Tube Fluidity Tester

This device evaluates the fluidity (flow length) of aluminum melt and how it is affected by various casting conditions (such as temperature), oxides, and additives. Its most distinct feature is the use of Pyrex™ (heat-resistant glass straight tubes) for the measurement section.

Unlike the traditional "Spiral Test" (Spiral Mold), where comparing standard samples against other conditions is difficult, this device makes sample observation and length measurement extremely easy. It significantly reduces testing workload and enables more accurate comparative evaluations.

Flux Feeder (Automated Flux Injection System)

Performing manual flux treatment consistently and correctly is no easy task. It requires stirring the entire molten metal from the bottom of the furnace for at least 10 minutes. This process often leads to quality variations depending on the operator. It is also grueling physical labor—especially in the summer heat—and carries the risk of injury.

By introducing this Flux Feeder, even first-year staff or those with less physical strength can achieve veteran-level processing quality. We have also resolved common issues found in conventional feeders, such as "clogging" and "uneven discharge." KANAE’s "Truly Usable Feeder" reduces workload, helps prevent staff turnover, accelerates the training of new rookies, and realizes work standardization and quality stability.

Advanced Flux for Modern Casting

The aluminum casting landscape is undergoing a dramatic transformation. Factors such as "lower holding temperatures" for energy conservation, the shift toward "Gigacasting," and variations in ingot properties based on origin are changing the rules of the game.

Lower holding temperatures (Energy saving / Carbon neutrality)

Increased mold temperatures and altered cooling cycles

Complex designs and the rise of Gigacasting

Variations in ingot quality due to country of origin, manufacturer, or lot differences

Traditional methods and conventional wisdom are no longer sufficient to handle these changes. KANAE has completely redesigned our flux formulations to meet these challenges. Through rigorous thermal analysis and repeated on-site field trials, we provide flux solutions optimized specifically for the "Modern Casting Environment."

Grain Refiners & Modifiers (Si Modification / Mg Protection)

High-Grade Refiners and Modifiers with Minimized Impurities

We provide Aluminum Grain Refiners (Al-Ti-B) and various Modifiers (B/Sr/Be, etc.). KANAE strictly selects only high-quality products with minimal impurities that demonstrate reliable effectiveness against shrinkage porosity and pressure leakage.

By eliminating the risk of defects caused by the additives (master alloys) themselves, we ensure precise microstructure control exactly as intended. These are professional-grade additives for foundries seriously committed to reducing casting defects.

Casting Clinic! ~ Ask Kanae ~

Characters

Nagisa (Second-year member of the foundry department) - Bright and positive. Never gets discouraged by failures and tackles improvements head-on. Curious and quick to jump on new technologies. Talks a bit fast and wears her emotions on her sleeve. A STEM girl who loves numerical analysis. A note-taking fanatic who's detail-oriented. The protagonist who deepens her understanding through hands-on experience while being amazed by the insights LEIBNIZ reveals.

Yamasaki (President of Yamasaki Light Alloy Casting) - Late 50s. President of the company. Strict about numbers and quality, but a person of great depth who celebrates his employees' growth more than anyone. Tough in meetings, gentle on the shop floor. Enjoys driving and gardening as hobbies. Exceptionally strong in data management. The key person behind LEIBNIZ's adoption. The discerning leader who guides critical business decisions throughout the story.

Minato (Casting Department Manager) - Head of the foundry department. Over 20 years of field experience. Practical and straightforward with a hands-on approach. Values experience over theory but understands the importance of rational thinking. Strict yet caring toward younger staff. Enjoys fishing and golf as hobbies. Though initially conservative about KANAE's technology, he comes to appreciate Nagisa's growth and LEIBNIZ's thermal analysis, eventually becoming more proficient with it than Nagisa herself.

Kanae (Chief Engineer at KANAE Hi-Tec) - Technical support engineer at KANAE Hi-Tec. Explains things carefully and logically. An enthusiast who deeply loves thermal analysis with a true otaku spirit. Passionate about statistical mathematics and Python. Serves as both product guide and friendly face. Provides technical reassurance as the explainer throughout the story.

Episode 1 Challenges for Nagisa and Minato

Nagisa: "Another shrinkage cavity... The client pointed out hard spots, so we added more flux and worked hard on the treatment, but why aren't they decreasing...?"

Minato: "Still glued to that little book of yours, Nagisa? In the real world, experience is king. I understand the urge to innovate, but if the defect rate goes up, it's on your head. You get that, right?"

Nagisa: "Chief! The melt temperature and casting conditions are unchanged. Even with that massive increase in flux, the problem persists. It’s strange... We must be overlooking something."

Minato: "Chasing that ‘overlooked something' is a never-ending game. That's just how aluminum works. Always has been."

Minato: "Anyway, I'll fine-tune the next batch with my 'gut-puter.' You sit this one out, Nagisa."

Episode 2 Presidens Yamasaki and XX Industrial’s Sales Rep

Yamasaki: "I ordered a fix for the casting defects, but the rate is up again. It’s eating into our profits, plus we have to cover machining costs and broken tooling. With this many returns, we can't re-melt it all, and scrap value is peanuts. I've told Minato until I'm blue in the face that lot variation is fatal. It stops the client's line and destroys trust. They haven't exploded at us yet, but it's a ticking time bomb..."

Yamasaki: "We need to break through the limits of experience-based quality control."

Alright, decided. We're going to try the technical advisory service that Ohtani from XX Industrial Supply & Solutions introduced. His confident pitch really stuck with me: 'The fees might seem high at first, but with fewer defects, it pays for itself in no time. Plus, it builds your staff's wisdom, so it pays dividends in the long run.'

Ohtani: "Hello, XX Industrial, Ohtani speaking. Good afternoon, President! What can I do for you today? Oh, by the way, did you try that flux sample I left? Worked like a charm, didn't it?"

Yamasaki: "Ah, hello, Shohei. Actually... Minato insists on playing it safe with the usual stuff, so we haven't tried it yet. More importantly, remember that technical support service you introduced? I’d like to request that. We tried increasing the flux, but it’s just not working."

Episode 3 KANAE

"Mr. Ohtani informed me that you're looking to incorporate new insights and technologies into your aluminum casting. Today, I’ll start by explaining melt quality control using Thermal Analyzer, followed by an on-site trial. I understand you also want to test flux and feeder, depending on the results. This is a paid service, so I will conduct a thorough investigation. However, real mastery takes time—so to truly internalize the know-how, I highly recommend considering our annual technical support contract."

Kanae: "Oh, I haven't introduced myself properly! I'm Kanae from KANAE Hi-Tec. It's a pleasure to meet you all!"

Minato: "Right, Ms. Kanae. Yeah, yeah, nice to meet you." (Just another run-of-the-mill consultant. What kind of nonsense did she fill the President's head with? I bet I'm in for a lecture on useless academic theory. I don't buy this for a second! I told the boss I would handle this...!)

Nagisa: "Wait, Kanae... from KANAE Hi-Tec!?" (Yay! I just love learning new things! This is so exciting!)

Kanae: "Yup, that's me! Let's do this!"

Kanae: "Alright, let's go over melt quality control using Thermal Analyzer. You're familiar with the Aluminum-Silicon phase diagram, right?”

Kanae: "See this white line on the left? That's the standard Al-Si phase diagram you know. This is theoretical data based on pure materials, tested in a clean lab with controlled temperature and humidity. However, real production ingots contain impurities—even within JIS or ASTM specs—which shifts the curve to the red line.

In other words, it’s not solidifying at the temperature you assume. And you know exactly what kind of defects arise from delayed solidification. After all, we don't cast in a lab; we cast in the real world. Don't you think so, Mr. Minato?"

"The red phase diagram on the left connects to the cooling curve on the right via these blue dotted lines. Basically, the cooling curve shows the real temperature changes from the phase diagram, plotted over time on the X-axis. The Y-axis is temperature, just like in the diagram. You can clearly see the primary crystals and eutectic of AC4CH appearing on the curve.

T-h-i-s is the 'unfolded view' that reveals exactly what the aluminum and silicon are doing—something you won't find in any textbook. By the way, we aren't just doodling curves for fun. We're performing precise measurements and calculations. Take a look at the next figure."

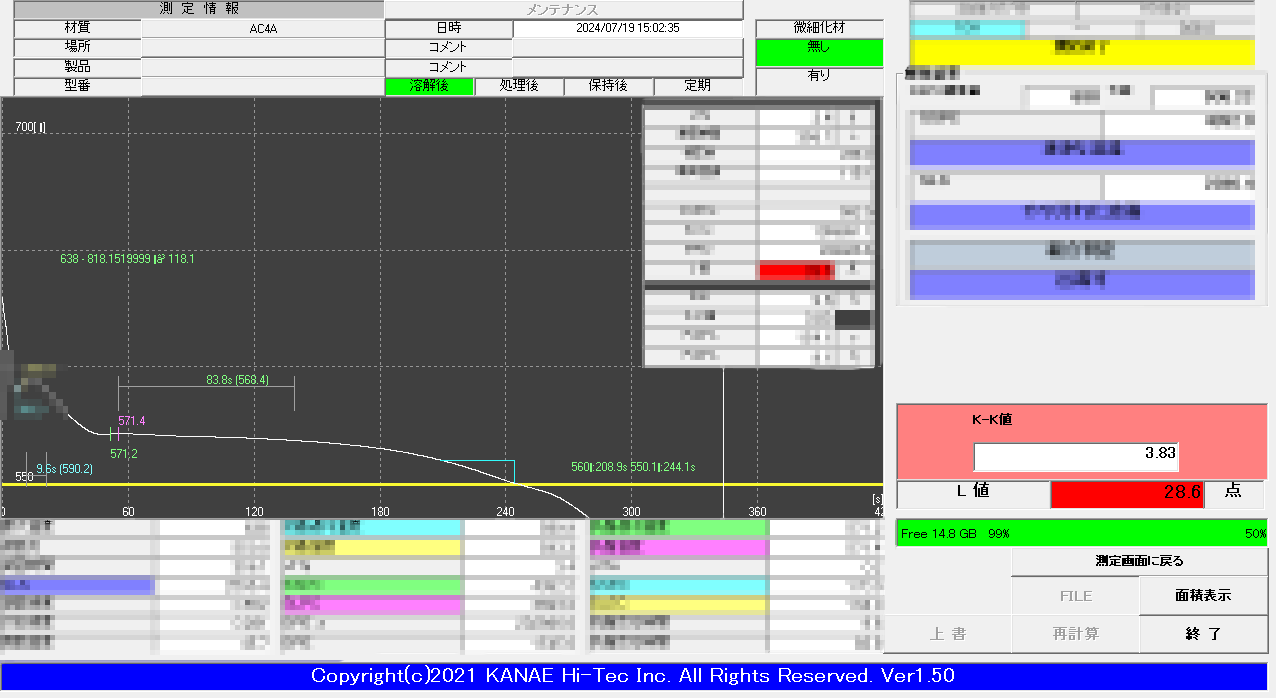

Kanae: "This screen shows an actual analysis. I've blurred out the specific metrics and calculations here for confidentiality, but for example, we are analyzing oxides and nucleation potential. The levels of these elements have a huge impact on casting defects."

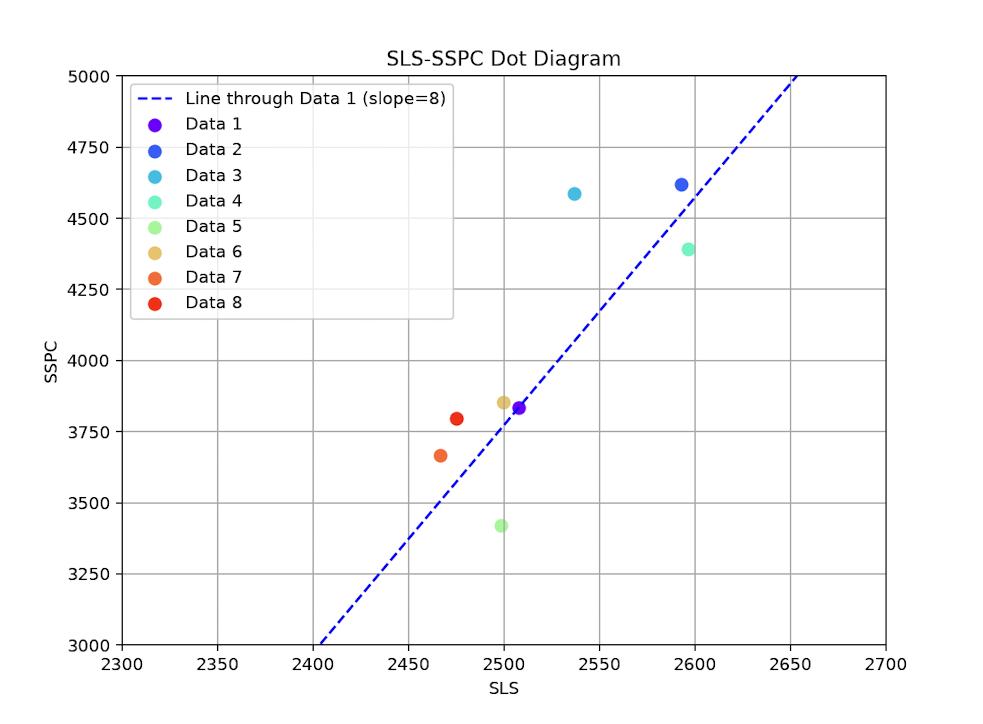

Kanae: "This is a free Python script we've released. Simply input the coordinates (x=SLS, y=SSPC) for each analysis, and it generates a Dot Diagram like this. I’ll cover how to evaluate the results in a future Episode, but basically, by tracking the movement of these dots, you can see whether the melt quality is improving or degrading. This allows for scientific selection of ingots and flux, as well as optimization of flux quantities and processing methods. Even if you're sourcing lower-cost materials, this tool helps you identify which options are least likely to cause defects."

"SLS and SSPC are proprietary metrics. SLS relates to 'Local Solidification Time,' while SSPC relates to 'Supercooling.' If the theory sounds complex, don't worry. Just use the free Python program to input the numbers, and it will plot this graph for you. It runs on smartphones and tablets, so feel free to customize and use it however you like!"

"Every melt can be mapped into these zones. The ideal target zone depends on your alloy composition, gating design, equipment, and casting parameters.

So... where does your melt fall?"

Kanae: "Shall we head to the shop floor?"

Yamasaki: "Ms. Kanae, thank you for the fascinating insights. Please proceed with the plan. I'll leave the rest in the Chief and Nagisa's hands."

Episode 4 On-site demonstration

Minato: "So, what exactly are you gonna do?"

Nagisa: "Chief, never mind that. Just move the skimming tool, please."

Nagisa: "So, this is the 'Leibniz' Thermal Analyzer!!"

Minato: "I moved the tools."

Nagisa: "Good job, Chief! You're very handy today."

Kanae: "Anyway... I'll just plug into this 100V outlet. I'm connecting the thermocouple cable to the built-in temp controller... and placing the sampling cup on the stand."

Kanae: "This melt was treated with your standard amount of flux, correct? Alright, pouring the melt into the cup now..."

Kanae: "The trick to high accuracy is to pour in one smooth motion—don't hesitate—and let it overflow. Then, cover it with a pail to shield it from the wind and ambient temperature. This ensures consistent results, whether it's summer or winter."

5 minutes later

Nagisa: "So, what's the verdict?"

Kanae: "Just as I suspected, the melt is dirty. I could tell just by how the melt reacted when I moved the ladle through the crucible, but the oxide levels are high. There are actually two types of oxides, but I'll explain that another time. The cause is either insufficient flux, or the flux itself isn't working. Shall we try adding more flux, treating it, and measuring again? If the results get worse after that, it means this flux is ineffective."

Re-analysis after re-treatment

5 minutes later

Kanae: "I hope you don't take this the wrong way, but your flux might be ineffective—or simply the wrong type. It relates to those 'two oxide types' I mentioned. If the flux were working, it would remove the harmful oxides, so this number would be lower. Meanwhile, it would enhance the nucleation sites, making that one higher. If you had zero defects, it wouldn't matter. But since you do, they won't go away unless we fix this. Looking at these numbers... aren't you seeing gas defects and misruns? It also suggests internal residual stress, so... deformation after machining?"

Minato: "You can figure that out from just this?"

Kanae: "Yes. Plotting the values on the SLS-SSPC matrix reveals it all."

SLS-SSPC Matrix