Solusi Masalah Pengecoran Aluminium & Kontrol Kualitas

“Kualitas Cor bermula dari Kualitas Logam Cair.”

Cacat yang Sudah Anda Anggap "Mustahil", Bisa Diperbaiki. Klinik Penanggulangan Cacat Pengecoran Aluminium & Perbaikan Kualitas Logam Cair dengan Analisis Termal

Analisis & Diagnosis Kualitas Logam Cair

Analisis Termal melampaui batasan Simulasi Aliran (Flow Simulation). Apa penyebab krusial yang tidak diperhitungkan oleh simulasi?

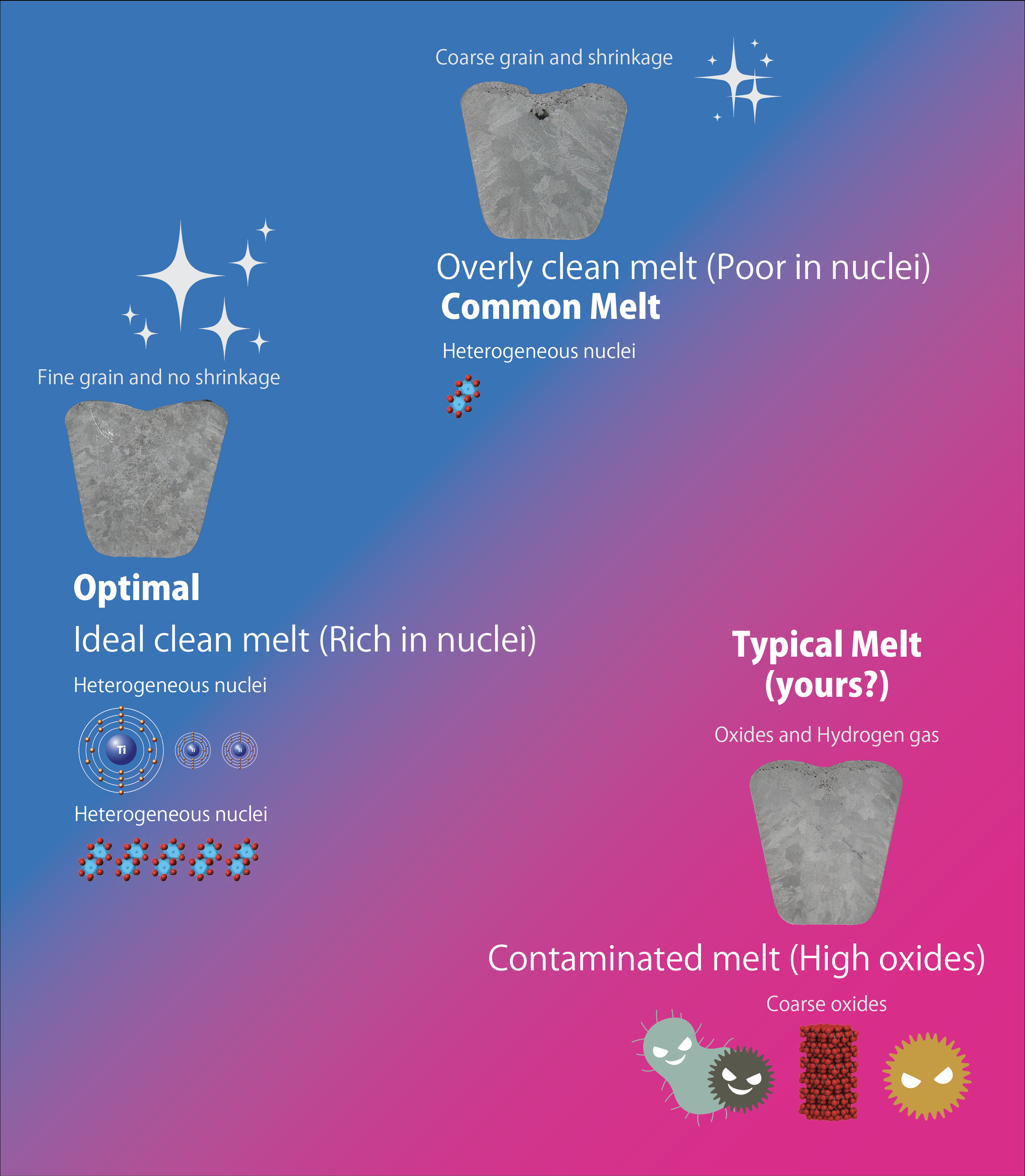

Penanggulangan cacat coran aluminium yang disebabkan oleh Ingot atau logam cair adalah keahlian utama KANAE. Oksida dalam logam cair ada yang "baik" dan "jahat". Teknologi Analisis Termal kami bahkan telah membuktikan keberadaan "cacat akibat logam cair yang terlalu bersih", sebuah fenomena yang jarang diketahui sebelumnya.

Lapangan sebenarnya bukanlah kondisi steril seperti laboratorium yang terkontrol. Oleh karena itu, kami menyediakan teknologi yang disesuaikan dengan "Realitas Lapangan" di mana terdapat kotoran dan fluktuasi, bukan teori lingkungan ideal. Karena di lapangan terdapat kebenaran yang lebih kompleks.

[Cacat yang dapat diurai dengan Analisis Termal]

Hard Spots, Inklusi

Penyusutan (Shrinkage), Porositas mikro, Porositas gabungan

Misrun, Cold shuts (Kulit ganda / Oxide films)

Penyusutan/retak sudut, Kebocoran (Leak)

Penurunan sifat mekanik (Kekuatan tarik, Proof stress, Elongasi, Kekerasan)

Perlakuan panas T6 tidak efektif (Efek pengerasan tidak tercapai)

Selain berbagai penyebab cacat ini, korelasi dengan Gas Hidrogen kini juga masuk dalam cakupan analisis kami.

Analisis Material & Dukungan Optimalisasi Proses

Mengapa cacat tidak hilang meskipun menggunakan Simulasi Aliran? Karena ada faktor penting yang tidak diperhitungkan.

Kemampuan analisis yang memahami Ingot dari seluruh dunia Kami telah menganalisis Ingot paduan aluminium dari Jepang, Tiongkok, Timur Tengah, Eropa, dan berbagai negara lainnya. Ingot memiliki "kebiasaan" tersendiri tergantung negara produksi dan produsennya. Di pabrik yang pengelolaan oksida atau silikonnya lemah, sifat material bisa berubah drastis hanya karena pergantian musim atau Lot produksi.

"Produk Bagus" bisa dibuat bahkan dengan "Material Murah" Dengan melakukan Analisis Termal pada Ingot, kita bisa mengetahui perlakuan logam cair (Melt Treatment) apa yang diperlukan untuk menghasilkan produk bagus. Bahkan saat menggunakan Ingot murah atau 100% Scrap Return untuk memangkas biaya, Analisis Termal memungkinkan pemilihan dan penanganan terbaik.

Pelatihan untuk menanamkan teknologi dalam organisasi Jika diminta, kami akan melakukan survei lapangan dan memberikan kuliah tentang perlakuan logam cair yang optimal berdasarkan hasil analisis. Pelatihan tindak lanjut (Follow-up) secara berkala juga tersedia agar teknologi tersebut mengakar di lapangan.

Pertama, silakan ajukan permintaan analisis Ingot. Jika memungkinkan, mohon kirimkan juga Scrap Return dan Flux yang sedang Anda gunakan. Ini akan memungkinkan kami membuat laporan diagnosis yang lebih akurat sesuai dengan realitas lapangan Anda.

Sistem Analisis Termal

Peralatan profesional yang kami gunakan dalam bimbingan teknis, kini tersedia untuk perusahaan Anda. Manfaat terbesar dari sistem ini adalah "Visualisasi" (Kuantifikasi) kualitas logam cair aluminium.

Tidak lagi mengandalkan intuisi atau pengalaman semata, melainkan departemen Teknik Produksi menetapkan "Standar Kelulusan (Score)", dan bagian produksi mematuhinya. Hal ini memungkinkan departemen Teknik dan Pengecoran untuk berkomunikasi menggunakan "Angka (Data)" yang sama, yang secara langsung mengarah pada stabilisasi kualitas dan Penurunan Tingkat Cacat (Defect Rate Reduction).

Cawan Sampling Presisi

Pengukuran yang akurat dimulai dari "Cawan Sampling (Sampling Cup)" yang diperhitungkan dengan tepat. Cawan KANAE telah dioptimalkan "ukuran butir pasir, berat, dan struktur pembuangan panasnya" khusus untuk analisis termal aluminium cair, serta dilengkapi dengan Termokopel (Thermocouple) presisi tinggi.

Tingkat akurasi pengukuran ini, yang dicapai melalui desain khusus, tidak dapat ditiru oleh cawan untuk Besi Cor (Cast Iron) atau produk tiruan lainnya.

Alat Solidifikasi Vakum Super Cepat

Sejatinya, alat vakum berfungsi untuk "mengurung" gas di dalam sampel untuk dievaluasi. Namun, alat konvensional memiliki kecepatan vakum yang lambat, sehingga gas lolos dari permukaan sebelum logam membeku. Ini persis seperti mengukur kadar karbonasi pada "Coca-Cola yang sudah kempes (tanpa gas)".

Di lapangan, sering kali kecepatan vakum diperlambat karena takut "gelembung pecah/muncrat", padahal itu terbalik. Logam yang muncrat adalah bukti bahwa gas yang tersisa terlalu banyak. Jika Anda memperlambat kecepatan untuk membiarkan gas keluar, analisis mungkin menunjukkan hasil "masuk standar", tetapi produk coran asli akan tetap memiliki cacat gas. Ini adalah kontradiksi yang berbahaya.

Dengan teknologi "Rapid Vacuum (Vakum Cepat)" KANAE yang tidak memberi celah bagi gas untuk lolos, Anda dapat mengevaluasi "Kandungan Gas Sejati (True Gas Content)" tanpa manipulasi.

Alat Uji Fluiditas Tipe Pipa Lurus

Karena menggunakan pipa kaca, aliran logam menjadi "Terlihat". Pengukuran pun lancar.

Alat ini digunakan untuk mengevaluasi Fluiditas (Panjang Aliran) logam cair aluminium serta dampak dari berbagai kondisi pengecoran (seperti suhu), oksida, atau Aditif (Additives). Fitur utamanya adalah penggunaan Pyrex™ (Pipa Kaca Tahan Panas) pada bagian pengukuran.

Berbeda dengan "Uji Spiral (Spiral Test)" konvensional yang sulit dibandingkan dengan sampel standar, alat ini membuat pengamatan sampel dan pengukuran panjang menjadi sangat mudah. Ini mengurangi beban kerja pengujian dan memungkinkan evaluasi perbandingan yang lebih akurat.

Mesin Pengumpan Flux (Flux Feeder)

Melakukan proses Fluxing manual dengan kualitas konsisten bukanlah hal mudah. Karena diperlukan pengadukan seluruh logam cair dari dasar tungku selama 10 menit terus-menerus. Proses ini rentan terhadap variasi kualitas antar operator, dan terutama di musim panas, ini menjadi Kerja Berat (Hard Labor) yang berisiko cedera.

Jika menggunakan Flux Feeder ini, bahkan staf tahun pertama atau mereka yang fisiknya kurang kuat dapat mencapai kualitas proses setara dengan Veteran. Kami telah mengatasi masalah pada feeder konvensional seperti "Penyumbatan (Clogging)" atau "Keluaran tidak merata". Feeder KANAE yang "Benar-benar Bisa Dipakai di Lapangan" akan mengurangi beban kerja, membantu mencegah Turnover Karyawan, mempercepat kemandirian staf baru, serta mewujudkan Standardisasi Kerja dan kualitas yang stabil.

Flux (Flux / Fluks)

Lingkungan pengecoran aluminium sedang mengalami perubahan drastis. Faktor-faktor seperti penurunan suhu Holding untuk Hemat Energi, tren Gigacasting, dan variasi kualitas Ingot berdasarkan asal produksinya sedang mengubah aturan main.

Penurunan suhu Holding (Hemat energi / Netralitas Karbon)

Kenaikan suhu cetakan dan perubahan siklus pendinginan

Desain rumit dan pergeseran ke Gigacasting

Variasi kualitas Ingot akibat perbedaan negara produksi, produsen, atau Lot

Metode lama tidak lagi memadai untuk menangani perubahan ini. KANAE telah merancang ulang Flux kami. Melalui Analisis Termal yang ketat dan Uji Coba Lapangan (Field Trials) berulang kali, kami menyediakan Flux yang dioptimalkan untuk "Lingkungan Pengecoran Modern".

Penghalus Butir & Modifier

Penghalus Butir dan Modifier High-Grade dengan impuritas yang diminimalkan.

Kami menyediakan Grain Refiner (Ti-B) dan berbagai Modifier (B/Sr/Be, dll.) untuk pengecoran aluminium. KANAE menyeleksi secara ketat hanya produk berkualitas tinggi dengan sedikit kotoran, yang terbukti efektif dalam mengatasi Penyusutan (Shrinkage) dan Kebocoran (Leak).

Dengan menghilangkan risiko cacat yang disebabkan oleh aditif (Master Alloys) itu sendiri, kami mewujudkan Kontrol Struktur Mikro (Microstructure Control) yang sesuai keinginan. Ini adalah aditif Spesifikasi Profesional bagi pabrik yang serius ingin mengurangi cacat pengecoran.

Casting Clinic! ~ Ask Kanae ~

Characters

Nagisa (Second-year member of the foundry department) - Bright and positive. Never gets discouraged by failures and tackles improvements head-on. Curious and quick to jump on new technologies. Talks a bit fast and wears her emotions on her sleeve. A STEM girl who loves numerical analysis. A note-taking fanatic who's detail-oriented. The protagonist who deepens her understanding through hands-on experience while being amazed by the insights LEIBNIZ reveals.

Yamasaki (President of Yamasaki Light Alloy Casting) - Late 50s. President of the company. Strict about numbers and quality, but a person of great depth who celebrates his employees' growth more than anyone. Tough in meetings, gentle on the shop floor. Enjoys driving and gardening as hobbies. Exceptionally strong in data management. The key person behind LEIBNIZ's adoption. The discerning leader who guides critical business decisions throughout the story.

Minato (Casting Department Manager) - Head of the foundry department. Over 20 years of field experience. Practical and straightforward with a hands-on approach. Values experience over theory but understands the importance of rational thinking. Strict yet caring toward younger staff. Enjoys fishing and golf as hobbies. Though initially conservative about KANAE's technology, he comes to appreciate Nagisa's growth and LEIBNIZ's thermal analysis, eventually becoming more proficient with it than Nagisa herself.

Kanae (Chief Engineer at KANAE Hi-Tec) - Technical support engineer at KANAE Hi-Tec. Explains things carefully and logically. An enthusiast who deeply loves thermal analysis with a true otaku spirit. Passionate about statistical mathematics and Python. Serves as both product guide and friendly face. Provides technical reassurance as the explainer throughout the story.

Episode 1 Challenges for Nagisa and Minato

Nagisa: "Another shrinkage cavity... The client pointed out hard spots, so we added more flux and worked hard on the treatment, but why aren't they decreasing...?"

Minato: "Still glued to that little book of yours, Nagisa? In the real world, experience is king. I understand the urge to innovate, but if the defect rate goes up, it's on your head. You get that, right?"

Nagisa: "Chief! The melt temperature and casting conditions are unchanged. Even with that massive increase in flux, the problem persists. It’s strange... We must be overlooking something."

Minato: "Chasing that ‘overlooked something' is a never-ending game. That's just how aluminum works. Always has been."

Minato: "Anyway, I'll fine-tune the next batch with my 'gut-puter.' You sit this one out, Nagisa."

Episode 2 Presidens Yamasaki and XX Industrial’s Sales Rep

Yamasaki: "I ordered a fix for the casting defects, but the rate is up again. It’s eating into our profits, plus we have to cover machining costs and broken tooling. With this many returns, we can't re-melt it all, and scrap value is peanuts. I've told Minato until I'm blue in the face that lot variation is fatal. It stops the client's line and destroys trust. They haven't exploded at us yet, but it's a ticking time bomb..."

Yamasaki: "We need to break through the limits of experience-based quality control."

Alright, decided. We're going to try the technical advisory service that Ohtani from XX Industrial Supply & Solutions introduced. His confident pitch really stuck with me: 'The fees might seem high at first, but with fewer defects, it pays for itself in no time. Plus, it builds your staff's wisdom, so it pays dividends in the long run.'

Ohtani: "Hello, XX Industrial, Ohtani speaking. Good afternoon, President! What can I do for you today? Oh, by the way, did you try that flux sample I left? Worked like a charm, didn't it?"

Yamasaki: "Ah, hello, Shohei. Actually... Minato insists on playing it safe with the usual stuff, so we haven't tried it yet. More importantly, remember that technical support service you introduced? I’d like to request that. We tried increasing the flux, but it’s just not working."

Episode 3 KANAE

"Mr. Ohtani informed me that you're looking to incorporate new insights and technologies into your aluminum casting. Today, I’ll start by explaining melt quality control using Thermal Analyzer, followed by an on-site trial. I understand you also want to test flux and feeder, depending on the results. This is a paid service, so I will conduct a thorough investigation. However, real mastery takes time—so to truly internalize the know-how, I highly recommend considering our annual technical support contract."

Kanae: "Oh, I haven't introduced myself properly! I'm Kanae from KANAE Hi-Tec. It's a pleasure to meet you all!"

Minato: "Right, Ms. Kanae. Yeah, yeah, nice to meet you." (Just another run-of-the-mill consultant. What kind of nonsense did she fill the President's head with? I bet I'm in for a lecture on useless academic theory. I don't buy this for a second! I told the boss I would handle this...!)

Nagisa: "Wait, Kanae... from KANAE Hi-Tec!?" (Yay! I just love learning new things! This is so exciting!)

Kanae: "Yup, that's me! Let's do this!"

Kanae: "Alright, let's go over melt quality control using Thermal Analyzer. You're familiar with the Aluminum-Silicon phase diagram, right?”

Kanae: "See this white line on the left? That's the standard Al-Si phase diagram you know. This is theoretical data based on pure materials, tested in a clean lab with controlled temperature and humidity. However, real production ingots contain impurities—even within JIS or ASTM specs—which shifts the curve to the red line.

In other words, it’s not solidifying at the temperature you assume. And you know exactly what kind of defects arise from delayed solidification. After all, we don't cast in a lab; we cast in the real world. Don't you think so, Mr. Minato?"

"The red phase diagram on the left connects to the cooling curve on the right via these blue dotted lines. Basically, the cooling curve shows the real temperature changes from the phase diagram, plotted over time on the X-axis. The Y-axis is temperature, just like in the diagram. You can clearly see the primary crystals and eutectic of AC4CH appearing on the curve.

T-h-i-s is the 'unfolded view' that reveals exactly what the aluminum and silicon are doing—something you won't find in any textbook. By the way, we aren't just doodling curves for fun. We're performing precise measurements and calculations. Take a look at the next figure."

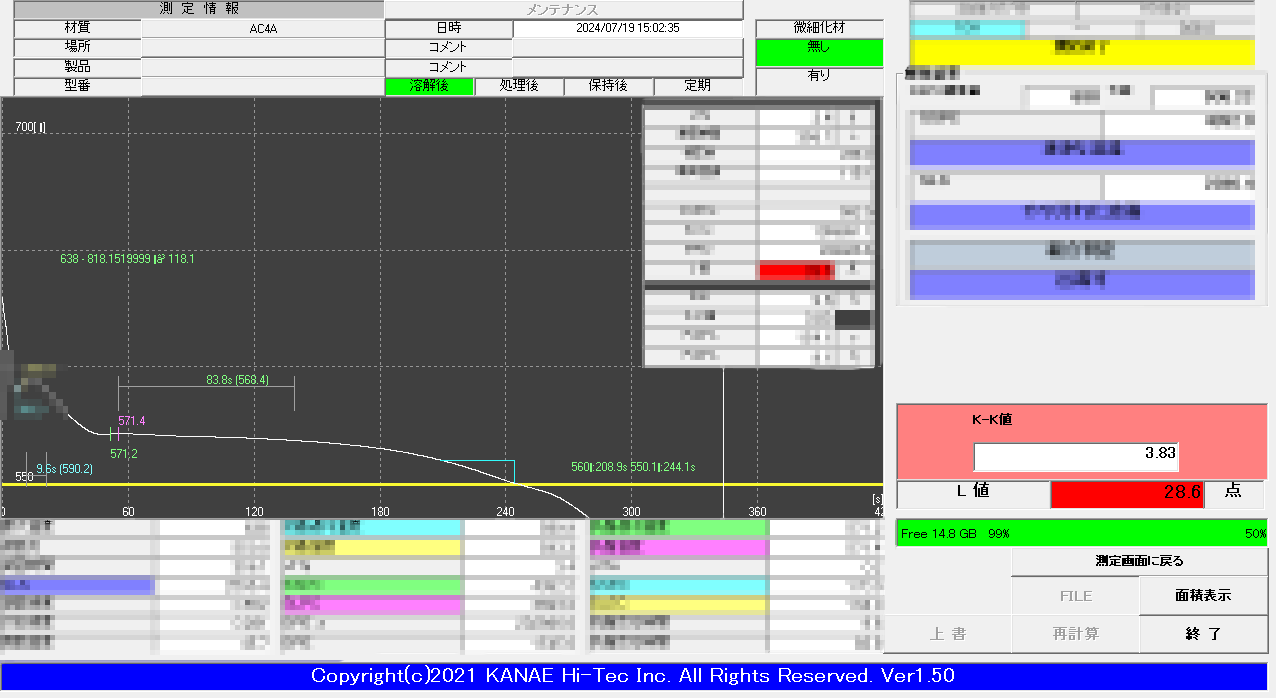

Kanae: "This screen shows an actual analysis. I've blurred out the specific metrics and calculations here for confidentiality, but for example, we are analyzing oxides and nucleation potential. The levels of these elements have a huge impact on casting defects."

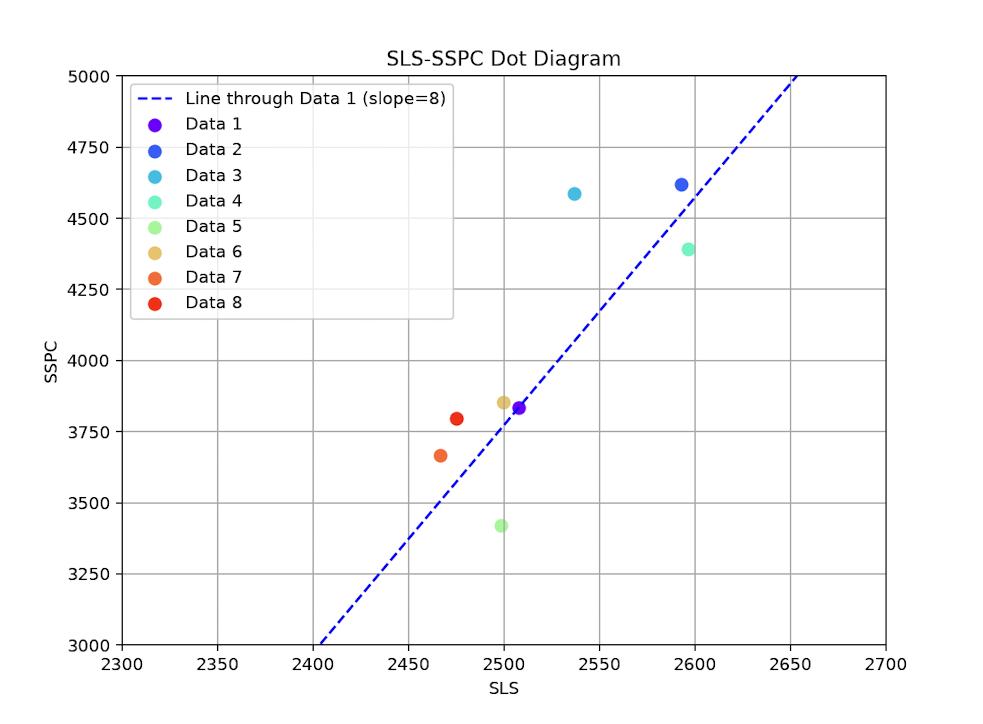

Kanae: "This is a free Python script we've released. Simply input the coordinates (x=SLS, y=SSPC) for each analysis, and it generates a Dot Diagram like this. I’ll cover how to evaluate the results in a future Episode, but basically, by tracking the movement of these dots, you can see whether the melt quality is improving or degrading. This allows for scientific selection of ingots and flux, as well as optimization of flux quantities and processing methods. Even if you're sourcing lower-cost materials, this tool helps you identify which options are least likely to cause defects."

"SLS and SSPC are proprietary metrics. SLS relates to 'Local Solidification Time,' while SSPC relates to 'Supercooling.' If the theory sounds complex, don't worry. Just use the free Python program to input the numbers, and it will plot this graph for you. It runs on smartphones and tablets, so feel free to customize and use it however you like!"

"Every melt can be mapped into these zones. The ideal target zone depends on your alloy composition, gating design, equipment, and casting parameters.

So... where does your melt fall?"

Kanae: "Shall we head to the shop floor?"

Yamasaki: "Ms. Kanae, thank you for the fascinating insights. Please proceed with the plan. I'll leave the rest in the Chief and Nagisa's hands."

Episode 4 On-site demonstration

Minato: "So, what exactly are you gonna do?"

Nagisa: "Chief, never mind that. Just move the skimming tool, please."

Nagisa: "So, this is the 'Leibniz' Thermal Analyzer!!"

Minato: "I moved the tools."

Nagisa: "Good job, Chief! You're very handy today."

Kanae: "Anyway... I'll just plug into this 220V outlet. I'm connecting the thermocouple cable to the built-in temp controller... and placing the sampling cup on the stand."

Kanae: "This melt was treated with your standard amount of flux, correct? Alright, pouring the melt into the cup now..."

Kanae: "The trick to high accuracy is to pour in one smooth motion—don't hesitate—and let it overflow. Then, cover it with a pail to shield it from the wind and ambient temperature. This ensures consistent results, whether it's summer or winter."

5 minutes later

Nagisa: "So, what's the verdict?"

Kanae: "Just as I suspected, the melt is dirty. I could tell just by how the melt reacted when I moved the ladle through the crucible, but the oxide levels are high. There are actually two types of oxides, but I'll explain that another time. The cause is either insufficient flux, or the flux itself isn't working. Shall we try adding more flux, treating it, and measuring again? If the results get worse after that, it means this flux is ineffective."

Re-analysis after re-treatment

5 minutes later

Kanae: "I hope you don't take this the wrong way, but your flux might be ineffective—or simply the wrong type. It relates to those 'two oxide types' I mentioned. If the flux were working, it would remove the harmful oxides, so this number would be lower. Meanwhile, it would enhance the nucleation sites, making that one higher. If you had zero defects, it wouldn't matter. But since you do, they won't go away unless we fix this. Looking at these numbers... aren't you seeing gas defects and misruns? It also suggests internal residual stress, so... deformation after machining?"

Minato: "You can figure that out from just this?"

Kanae: "Yes. Plotting the values on the SLS-SSPC matrix reveals it all."

SLS-SSPC Matrix